This translation was done by Michaela Gibbion (known in the SCA as

Maeva Eriksdottir). Thank you on behalf of DARC and the re-enactor

community.

Viking Age crafts in Ribe - A summary

by Mogens Bencard, Ribe

with assistance from Kristina Ambrosiani, Lise Bender Jørgensen,

Helge Brinch Madsen. Ingrid Nielsen and Ulf Näsman

Geography of Ribe

The settlement Ribe is located about 6km off the coast at the shore of

the Ribe Au that connects Ribe with both the Baltic Sea [through the

Kattegat] and the North Sea behind the Isles Fanö,

Mandö and Römö. The area around Ribe belongs

to the most northern part of the wadden sea reaching continuously from

the firths of Elbe, Weser and Rhine protected by a long row of islands

North of Ribe the western coast of Jutland changes its character. The

wadden sea recedes and there are no more islands protecting the actual

coast. Two good sized flood plains, the Ribe Au and the Koenigsau, run

into the most northern part of the wadden sea. The firth of the

Koenigsau is mostly shallow with numerous shoals whereas the Ribe Au

continue a clearly defined path into the wadden sea.

Taking the geographical position Ribe's into consideration with the

topic of this article it is obvious that Ribe is located at the most

northern point of the natural trade lines of the Frisian and that the

Ribe Au is the most northern trade route used to connect with the

jutlandic back lands.

While Hedeby was Jutland's portal to the Baltic Sea Ribe was its

equivalent to the North Sea. Whether there has been a trade route

across Jutland from Ribe during the early viking age similar to the

Hedeby-Hollingstedt-Route or not is debatable.

History – the written sources

The number of written sources available on the early history of Ribe

are numerous and extremely informative especially considering that Ribe

is a Scandinavian settlement. Here is a listing of the most important

accounts:

Ribe is first mentioned around the year 860 — during the last

years of Ansgar. According to Rimbert, Angar's biographer, the king

presents the bishop with a piece of land and the permission to build a

church.

1 Furthermore he also

receives permission for permanent

residence of a clergyman. Following Birka and Hedeby, Ribe becomes

Ansgar's third mission in Scandinavia.

In connection with the synod in Ingelheim in 948 three danish bishops

are being mentioned : the bishop of Schleswig [Hedeby], Århus

and Ribe.

2 This is the first

account of danish bishops known to us.

Odinkar the Younger of Ribe, a bishop in the ii . century, may have

even reigned all of Jutland from his bishopric as there is evidence

that the bishopric of Arhus was abolished which was vacant in Slesvig

[this doesn't make any sense – perhaps a misquote ? Need look

up original text for this]

3

At the end of the 11th century Adam von

Bremen describes Ribe as a town surrounded by water flowing in from the

ocean over which you can travel to Frisia, England and Germany.

4

This source not only describes a town with trade connections along the

coat of the North Sea and across but also indicates that Ribe is

located exactly where it is known since the 12th century. It is safe to

assume that the aforementioned water describes the uniting streams of

the Ribe Au as no other location in this area meets those requirements

It is therefore proper to conclude from the written sources

- That Ribe is an urban settlement comparable in importance to the

archaeologically more renown settlements such as Birka and Hedeby.

- That Ribe was not only an established settlement during the

viking age but continued as a town. Adam von Bremen refers to Ribe as civitas.

The archaeological sources

Archaeologically the trade routes and other connections between Ribe

and surrounding areas can be proven back to the roman empire. Roman

coins were excavated at numerous places and in great numbers in the

extraordinarily rich living quarters of the field of

Dankirke southwest of Ribe.

The sequence of layers of this living quarter spans from the pre-roman

iron age to around the year 500 and contains a wide variety of finds

[ceramics, glass, jewelry, iron, bronze, silver, gold] as well as a

total of 73 coins of the age of the roman empire. The following coins

of more recent eras were found as well : 3 merovingian coins minted by

Madelinus between 689 and 716 in Dorestad, 2 English Sceattas from ca

725 and 8 Sceattas of probable Frisian origin of the late B. century.

There is the possibility that the living quarters at Dankirke were the

predecessor for the final settlement of Ribe, just as Helgö

was for Birka

5

There are several viking age finds at Ribe and surrounding areas

whereas numerous excavations in the medieval city center did not

provide any clues of either the time of Ansgars or following centuries

that would have proven that Ribe developed at the same location where

it is today.

Only when the excavated area was expanded to include the other side of

the Ribe Au in 1970 did the archaeologists gather positive evidence. A

series of probings in this area of town revealed a concentration of

cultural layers near S. Nikolaj Street that lead to two greater

archaeological excavations in 1974-1975 with support of the danish

archaeological society.

<Image 1>

Fig. 1. Detail of a city map of Ribe. Circles indicate excavation

locations that only provided medieval finds. Triangles indicate

excavations that also discovered Viking age finds.

A total of about 600 m

2 have been searched. The

cultural layers were between 2m and 3m strong, however, not even half

of those originated from the Viking age. About 60.000 finds have been

made of which about half are to be counted into the earliest time

period. The oldest phases of the settlement have to be divided into 4

main layers. The bottom layer consists of soil with traces of ploughing

with an ard. A grey layer of sand covers this ploughing layer [or might

be part of it]. This layer also provided remains of one, maybe two

wells as well as layer of waste consisting of iron scoria.

The whole area was completely covered by a waste layer during the

second phase which consists mainly of unrotten dung mixed in with

settlement waste that clearly points towards a settlement with trade

and crafts characteristics. Items that have been pressed into the

ploughing tracks of the first layer indicate that there hasn't been

much time between phase 1 and 2. Phase 2 and 3 seem to share an equally

close connection. This is evident in the stratigraphy as well as in the

items found in layer 3 that share both character/style and time period

as the items of layer 2.

The sequence of layers, however, shows a different composition.

Alternating there are thinner layers with a concentration of charcoal,

ashes and top soil oftentimes in connection with a fire pit or hearth

and other relatively thick layers of sand or top soil mixed with sand.

In this text we will refer to those thin layers as “Activity

horizons” and the separating layers “filling

layers”. The term “ground level layer”

has not been used in regard to the activity horizon layers as there are

no signs of wall constructions or similar structures.

Two such activity horizons were identified as a bead maker's workshop

and a bronze caster's workshop.

Incidentally only 2 sunken houses were found in the excavated area in

connection with layer 3; they are located at edge of the layer. A

double row of posts with interwoven brushwood was found but couldn't be

classified as to its function due to its relatively small size. It

could either be the wall of a house or perhaps a fence section. Layer 3

was disrupted and destroyed in this area due to construction works in

the 19th century.

It is very difficult to interpret the various layers that make layer 3.

The biggest obstacle lies in the many construction works this area has

been experienced that disrupted and destroyed the older layers

especially the rubbish pits of the 17th century. A larger connected

area has not been excavated and examined. However, it became obvious

that in this rural simple area ingenious and artistic crafts like the

production of beads thrived.

The activity horizons were layered on top of each other and thus tend

to create peaks with waste filling the spaces in between. None of those

peaks have been excavated fully. It was only possible to spot check

through several of them. In one of those samples containing the

beadmaker’s workshop, several of those activity horizons were

evident.

Phase 4 basically provides another waste layer on top of which there

are finally the layers of the 13./14th century. It is difficult to

understand this particular layer as it is very rich in objects and

lacking in traces of actual settlement.

The following theory can be presented without claiming final

interpretation: The first 3 of the 4 phases appear to show an increase

in activity at the location. A waste layer with signs of trade and

crafts was created over a former field. In direct follows evidence of

the continued presence of craftsmen and their workshops at the same

location. A possible explanation could be that the excavated area was

located alongside a settlement center and a such give proof of a

continued growth of this settlement. This settlement of which we found

traces of ploughed fields might not have been nearby, however, the

finds of waste and the aforementioned wells indicate it can't have been

far away.

6

<Image 2>

Fig. 2. Detail of a wall in profile of the courtyard showing layers and

phases. The drawing is simplified. Organic material was found in the

layers of phase 2. (Photo and drawing ASR).

Regarding phase 2 it appears that the settlement has been near the

waste area. However, two points need to be taken into consideration

- We cannot assume that the settlement of which we have found

evidence in the layers of phase 2 is an expansion of the settlement in

phase 1.

- It is also not possible to determine whether the waste was

created by a continued or a periodical settlement. The large quantities

of unrotten dung appear to indicate a continued settlement. It

definitely indicates that there have been barns from which the dung

together with other waste was collected and removed. The great amount

of dung also point towards a great number of animals, possibly greater

than needed for the diet of the population of the settlement.

Assuming that at this early point in time Ribe did already have an

established trade rout for Jutland cattle then this fact cannot be used

to provide evidence for a continued settlement. This also applies to

the amount of found dog excrements.

<Image 3>

<Image 3b>

Fig.

3 a-b. Detail of a profile wall in the backyard of the art museum

showing layers and phases. The layers at the bottom of phase 3 include

the activity horizons of the bead maker workshop (Photo and drawing

ASR).

It appears that the work of the craftsman of phase 3 happened either

under the open sky or a fairly lightweight construction as it did not

leave any visible signs. This also appears to indicate a periodic

settlement; however, this theory is weakened by the existence of fire

pits obviously used for cooking and solid house constructions as living

quarters.

Summarizing those finds it can be said that the excavated material is

contradictory as well as too small in number to allow an educated

decision as to whether Ribe was a permanent settlement or rather a

periodically used market location. It is obvious; however, that it

hosted a rather active economy.

Age determination

Due to the planned publication of those finds the variety of finds were

divided into groups and handed over to a number of scientists for

examination and study. Independently they have systematically examined

the items in regards to the age determination which resulted in the

discovery that they stem from the B. and g. century. The only exception

is the waste of the comb maker workshop which originates mainly out of

phase 2.

Kristina Ambrosiani, Stockholm, one of the scientists working on the

project, reported a strong presence of combs with a D-shaped profile.

Comparing this type of comb to similar material from Birka and Hedeby

dates those most likely to the 10. century.

7

Coins allow for a more exact age determination.

8

30 coins have been

found in the oldest layers : 28 Sceattas, 4 of which are so called

"porcupines"

and 24 of the "Wodan-Type" . There are two more coins of which one

shows a hole drilled into the edge. Based on size they could be of

Arabic origin, unfortunately they are heavily corroded which makes it

impossible to determine this for sure.

<Image 4>

Fig. 4. The two main types of Sceattas. M. = 2:1. (Photo

Nationalmuseum).

The coins are scattered throughout the layers and belong to phase 2 as

well as phase 3 and 4. This arrangement also indicates that the coins

are part of the settlement's waste rather than a scattered coin hoard.

This is why they are valuable for the age determination.

Kirsten Bendixen comes to the following conclusion : “After

comparing treasure finds and scattered coin finds of the same time

period it can be said that the different types of sceattas found in

Ribe originated from Frisia where they were in use from ca 720 to

800.”

Since we were able to date a few coin finds from the lowlands to the

middle of this time period we are confident that after consistent study

of coin variants we are able to determine the age of the Ribe coins

even more closely. The characteristics of the scattered coin finds of

Ribe give the impression of a fairly widespread and common use of

money, however, sceattas haven't been in use much longer after the coin

reformation of Charlemagne in 790. Hedeby imitated the big thin

Schroetling of the Carolingian coinage since 825 where it acquired some

resemblance to the former sceatta. Actual sceattas have not been found

together with Hedeby coins. This strengthens the theory that the use of

sceattas was limited to a very small time period. It is therefore

possible to date phase 2 and 3 to the time period between 720 and 825

with the phases dating more into the latter half of the 8th century and

reaching into the following century. Those relatively exact methods of

age determination – such as dendrochronology - of such a rich

and diverse find such as Ribe can hopefully be beneficial to the study

of other settlement excavations.

Immediately on top of the earliest layers of phase 4 are horizons,

which point toward the 13th and 14th century. We are not going to

discuss the problems that the lack of continuity of the finds

throughout the viking age creates but would like to mention that

scattered finds of the early viking age do occur in a different area of

the settlement north of the Ribe Au. Also, at this time there is no

answer to the question of where the hypothetical city center was

located. However, west of the aforementioned excavation in 1976 a

smaller excavation with scattered and sparse finds that were no

different in content and date provided us with a completely different

order of the cultural layers and horizons.

Comparing the written sources with the currently available

archaeological sources we reason that the are of Ribe was continuously

settled since the 8th century. A placement shift of the settlement as

we know it from other earlier settlements in northern Europe seems very

unlikely for Ribe, except for a shift during the 12th and 13th century

from the northern towards the southern shore of the Au. With begin of

the 14th century the oldest part of town is always referred to as

»Suburbium«

9

The various crafts

As mentioned before the various finds were divided between the

scientists who agreed to publish both material and the results of their

studies. For those find categories that are still under examination the

following report is a preliminary account complemented by purely

archaeological-stratigraphical observations by Mogens Bencard.

The blacksmith10

There is plenty material that provides proof for this particular craft

from dross to fragments of burnt clay with bits of dross still clinging

to it. Since this material hasn't been studied yet, this report is of a

very cursory nature.

Aside from scattered finds the excavated material is concentrated at

two points of the settlement of which one refers to the transitional

time period of phase 1 to phase 2 and the other one to phase 3.

The waste appears to be the result of the workshop of just one smith

and there is no evidence that indicates that there has been an

extraction [working with ore] locally. The kind of dross mainly found

is the flattened dome shaped “calotte”

11

dross puttied with roughly crumbled white rock

<Image 5>

Fig. 5. Front of a flue stone made from clay M = ca. 1:3. (Photo ASR).

Since such admixtures occur with a variety of dross it is difficult to

discuss those found in Ribe as a stand alone kind. There is also a

great percentage of another kind of light grey, porous and spongy dross

which isn't documented for Hedeby and which cannot be connected to a

single particular craft in Ribe. In Lindholm Høje near

Aalborg this kind of dross was found in direct connection to the work

of the local smith.

In his study of the material of Hedeby Robert Thomsen managed to select

a type of dross which he referred to as

“winkelförmige Esseschlacken” [literally

“angle-shaped flue dross”]. The material of Ribe

does not support this type of dross as its production is rather

confusing. Among the finds of Ribe there are many examples of calotte

shaped dross molten together at an angle with pieces of red clay with

holes. In a number of cases the piece of clay was fully conserved and

shows a rounded edge. The front of this item made of clay is glossy

like glass, the back fired with a weathered texture. After noticing

those attributes it was possible to put several of the fragments

together which then create an approximately round shape with a hole in

the center. It is difficult to see anything but some kind of protective

shield for the bellows in those pieces, as stand alone flue stones.

During use a partial burning of the clay occurs whereas the other part

that doesn't get quite as hot flakes off more easily and after use

rather weathers. This creates an archaeological item which is referred

to as “flue dross” but is actually an independent

flue stone – similar for example to the Snaptun-stone

12

or

the soapstone fragments from Hedeby and Fyrkat.

13

One can imagine how those clay disks could have been a cover layer for

the front of an actual flue stone as Robert Thomsen hinted at in his

reconstruction. This theory is contradicted partially by the fact that

the clay disks show a weathered back, that soapstone does hold up well

against high temperatures and also partially the fact that the stone

from Hedeby shows burnt in dross at the front. In case this

interpretation proves correct it means that the angle shaped dross

consists of two pieces: a calotte shaped piece of iron dross molten

together with a piece of flue stone made from clay.

Bronze casting14

A great number of fragments of flue stones made from fired clay give

evidence of this craft. To date there is no exact number of those

fragments. There are also more than 300 fragments of crucibles as well

as more than 2000 fragments of molds made from clay of which about 200

are decorated. 25% of this material were found in the layers of phase

2, 5% are scattered finds of phase 3 and the remaining 70% belong to

the activity horizon of phase 3.

The activity horizon of phase 2 did not provide any firm evidence for

the fact that the bronze caster did actually work at this place since

for example no furnace had been found. However, in the center of the

activity horizons there is a shallow depression with where convex dross

covered with a flue stone has been found. A possible explanation is

that the craftsmen did not need a more elaborate and bigger furnace

than this. A small depression in the ground or maybe a mere piling of

charcoal into which the crucible was placed with bellows and flue stone

arranged besides it might not leave any clear archaeological evidence.

The strong concentration of waste in this 2m x 2m area as well as a

decrease of the same waste in the neighboring layers, however, makes it

very likely that this has been the workshop of a bronze caster.

Aside from remains of bronze in crucibles only little bronze remains

have been found in the area of the workshop. A connection between molds

and bronze objects found on site could not be verified. There are many

bronze items in the layers of phase 2 and 3. Only a very small number

of bronze items have been found – a few needles, 3 triangular

brooches, one small bowl-shaped brooch as well as fragments of a bigger

one. The number of undetermined bronze fragments

<Image 6>

Fig. 6. Oberkappe (links) und

Unterform für eine schalenförmige Spange. M = 2:3.

The great number of finds helps us understand the work process better.

15

It not only applies to the smith but also to the bronze caster that

there is one item that requires special attention. The many fragments

of fired clay are not fragments of the furnace but flue stones that

provided a protective shield for the bellows. In two cases it was

possible to reconstruct and put together complete front sides of those

items/ In Ribe those are predominantly square with an average side

length of 5-6cm. There is a hole in the center of about 1cm diameter

through which accommodated the tip of the bellow. Among the finds was a

iron tube which could have been the tip of a bellow. The front side of

the flue stones which pointed towards the fire are 1-2cm deep burnt to

glass. The backside is not preserved as it received too little heat and

thus crumbled away over the centuries. This type is known from

Helgö, Birka and Paviken in Sweden and some burial finds from

Sweden with examples up to 15cm strong. This item can also be

understood as a clay block that sat on the ground.

There are 4 types of crucibles.

- Thimble-shaped crucible

- Thimble-shaped crucible with a square handle to the side

- Closed crucible

- Low and flat crucible16

There are only a very few examples of the type 4 crucible known and it

is difficult to determine the percentage of the first two due to

fragmentary nature of many. The crucibles of type 3 are the ones that

are the least fragmented. Their heights range from 3.1 to 9.8 cm with

an outer diameter of 2-5.7cm which indicates that they were only used

to melt the bronze for one single item.

The many fragments enable the scientist to reconstruct the structure of

a mold with greater accuracy. The finds do not allow any information on

the actual model or the material out of which it was made but we will

look at this later in greater detail. The molds were shaped from clay

mixed with fine sand, glimmer and organic material [for example seeds

and chaff] and fired. They are between 1-2 cm thick [average 1.5cm].

All fragments belong to two-piece molds except for a fragment of a

three-piece mold.

The assembly went as follows: first the model was equipped with a

conical peg that later formed the spigot for the finished mold. The

clay of the top of the mold was modeled on to the top of the model,

most of the time worked in layers, so the details of the ornamentation

could be executed in greater accuracy. After drying the top was turned

over and the model removed and incisions made into the area around the

spigot. A piece of cloth approximately the thickness of the desired

piece of jewelry was placed inside the top part of the mold and soft

clay was pressed into the shallow depression to form the bottom. After

drying the bottom part of the mold both halves would be separated,

cloth and peg removed and if necessary holes for the needle clip cut

into the bottom part of the mold. Before using the mold it had to be

fired. This was done after putting both halves together and covering

them with a thin layer of clay – a way to ensure they were

fitted tightly together. We are not sure whether the molds were used

several times. At least the bottom half of the molds had to be broken

to remove the final piece. This is obvious in a small indention at the

lower part.

The fragments of molds of phase 2 show that keys with a round handle

were cast as well as other items such as needles. Only one single top

half for a bowl-shaped brooch of the small type has been excavated.

This type is also known from finds made on Bornholm. A brooch of this

type has been found in Ribe in the same layer, however, it cannot be

determined whether this brooch was manufactured in Ribe or not as no

decoration on the inside was preserved. This may be caused by the

structure consisting of thin layers which might have led to a flaking

off of the inside layer.

The approximately 200 decorated fragments of the actual bronze casting

workshop represent only a few different types. Among the finds is a

mold for a horse buckle, a mold for an equal arm brooch of the Troms

type as well asmoulds for two keys. The remaining decorated fragments

belong to the type of bowl-shaped brooch of the Berdal type D.

The elements of the ornaments of those molds are the same; however,

they are arranged in different ways so that the decoration changes from

brooch to brooch. The bronze caster could have use the same top mold

several times. It is however likely that he did not work with a

constant model for example a finished cast brooch. The method with the

greatest possibility is the use of an individually worked model made

from wax.

The Berdal brooch is well known form from western Scandinavia. To date

it has only been possible to tie one single brooch find from

Myklebostad in Norway to Ribe which is likely to have been manufactured

there. It is one of the mysteries of this time that there aren't many

found items that match the many discovered molds.

At last we would like to point out that there have been many finds of

iron pins for use with brooches. A stock of pins appears to have been a

typical part of stocked items for a bronze casting workshop.

The production of glass beads17

Aside from clay glass is the most common material found during the

excavations at Ribe. It appears in phase 2 as well as scattered finds

during phase 3. More so, two activity horizons of phase 3 have been

classified as workshops of bead makers.

<Image 7>

<Image 8>

Fig. 7-8. The two furnaces of the bead maker workshops back-to-back.

The lighter colored strips of the wall indicate a hearth whose function

hasn't been determined yet. In front the activity horizons have been

broken by a well dating from the Renaissance. (Photo ASR).

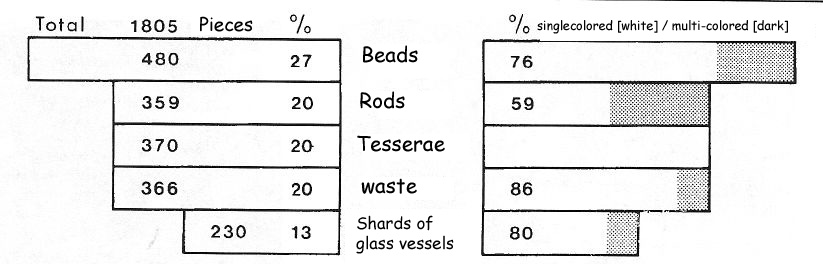

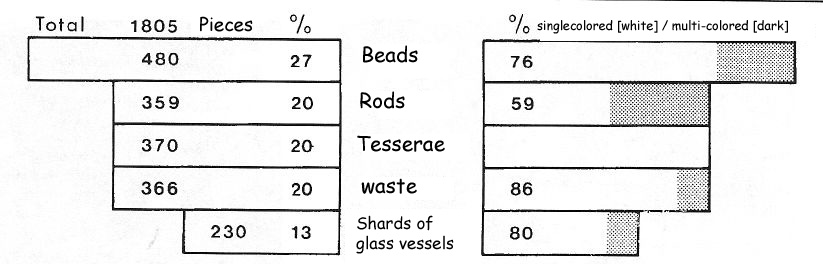

In total, ca. 1800 pieces of glass have been found. Of those 26% are

whole and fragmented beads 20% glass rods, 21% tesserae, 20% waste and

13% shards of glass containers. In addition the following have been

found : a piece of rose quartz, a piece of quartz, a piece of rock

crystal, a bead of amethyst, a carnelian bead as well as 2 fragments of

roman cameos with engravings of figurines

18

The aforementioned activity horizons contain a strong concentration of

glass. They are directly on top of each other separated only by a thin

layer of sand. Both horizons have a length of 4,40 m whereas it hasn't

been possible to determine the width as part so the area have been

disturbed and removed through later activities and some are located

outside the excavated field. Each horizon has a furnace in which the

concentration of glass and charcoal are the highest. It measures

50-60cm x 25-30cm. Both are partially scorched red. In the less

scorched parts of one furnace there was evidence that the clay had been

mixed with refractory clay. Both furnaces showed an even surface

without any depressions or elevated edges. In one corner of the one

furnace a burned item made from fired clay was found that resembled a

loom weight. It was slightly heavier than regular loom weights and

covered in molten glass on one side. It is very likely this is a flue

stone for the bead maker's furnace. (Fig. 7-8).

Of the ca 480 found beads 76% are single colored and 24% multi colored.

39% of the single colored beads are blue, 24% green and 17% white. The

remaining 20% are red, orange, yellow, purple and clear glass; a few

silver and gold foil beads have been found as well.

Fig. 9. Diagram of glass items sorted by category. (drawing: Ingrid

Nielsen).

The dominant color combination for multi colored beads is blue with

decoration of red and white lines: 36%. There are another 24% of beads

made from blue glass with different decoration. 14% were made from

reticella rods, 12% from black glass with yellow lines and 5%

millefiori beads. The remaining 9% are black, white, green and yellow

beads with different ornamental decoration. Multicolored beads are

predominantly round whereas single colored beads come in a much greater

variety of shapes.

Generally speaking the beads represent the 8th and 9th century and west

Scandinavia in style

19. Only a few types of

bead in very small

numbers can be counted towards imported goods whereas the rest can be

considered as produced in Ribe. Polished and drawn beads such as the

gold and silver foiled beads are most likely imported goods.

Most of the single colored beads have been created in roll technique ie

wounding the glass around a mandrel. Those beads could have been

produced in Ribe. This also applies to the multi colored beads with

either colored thread decoration as well as those from reticella rods

created in the same technique. Millefiori beads are a sparsely

represented group; however, the finds indicate that they have been

produced in Ribe.

Of ca. 360 rods and stringers 59% are single colored and 41% multi

colored . Of the single colored ones 39% are blue, 24% green, 17% red,

10% yellow, 9% white and 1% clear. Of all multi colored rods and

stringers 44% are millefiori, 34% simple rods with parallel differently

colored stripes and 21 % reticella.

Aside from the numerous finds of ready made single and multi colored

rods and stringers there are also “collections of

stringers” that show traces of manipulation with pliers. A

“collection of stringers” refers to a number of

multi colored stringers that are combined and molten into one thicker

rod that can be stretched and thus thinned to the desired thickness.

Both the existence of single colored as well as multi colored stringers

indicates they were produced in Ribe rather than imported.

Of ca. 370 pieces of tesserae 21% are made of blue glass, 21% of red,

15% of green and 15% of clear green glass with encased gold foil. The

remaining 20% are divided between clear, white, black, orange, brown,

yellow and purple glass.

<Image 10>

Fig. 10. Steps of the production of millefiori beads. a: unfinished rod

with blue threads and red and white flower pattern b: end of rod with

traces of pliers. Blue and white eye patterns with red frame c: rod

with eye patter in red-yellow-blue-white-blue. D: rod with blue and

yellow checker board pattern in red frame e: plate with alternating

blue and yellow checker board pattern and red and white eye pattern in

blue frame. f: Bead with checker board pattern of aforementioned plate

and blue and white eye pattern in red frame. Scale 1:2 sketch : P.-O.

Bohlin).

The existence of tesserae is considered firm evidence of a bead

production [or eventually the use of enameling for decoration]. The

finds of Ribe indicate clearly that tesserae were a trading

merchandise.

20 Scattered individual

finds for example a single piece

in Aggersborg, are somewhat inexplicable, however, they could have been

considered a curiosity or may have been used as an amulet. Wherever we

find considerable amounts of it it must be considered an imported raw

material for the production of glass items. So far there are no finds

dating earlier than the 8th century. Already published finds fit neatly

into the results of the Ribe excavations and draw a clear picture of

the budding Norse trade due to efficient organization of trade routes

with hubs such as Helgü, Paviken, Kaupang and the eldest of

them, Ribe. A recently discovered find of 62 tesserae in the rural area

of Stånga on Gotland can be considered evidence for the

particular nature of gotlandic trade

21

<Image 11>

Fig. 11. Examples of polychrome beads a: blue bead with red eyes and

white zigzag line b: blue bead with red and white lines in a garland

pattern c: blue bead of reticella and blue with red and white zigzag

line d: blue bead with a blue eye framed in red and white. Scale: 3:2.

(Sketch: P.-O. Bohlin).

In Ribe, tesserae appear to have been the most important raw material.

It is possible that they have been produced for this express purpose.

They were possibly introduced to Ribe via Western Europe but might also

have been produced in Italy.

22

The waste consists on one hand of remains of the imported raw material

and waste of the bead production itself on the other. It is comprised

of about 366 pieces of which 41% are blue, 14% multi colored, 15% green

and 10% red with the remaining 20% of clear, white, black, orange,

brown, yellow and purple glass.

The raw material was possibly imported in bigger blocks and broken into

smaller pieces at the workshop before it was molten in crucibles.

Numerous slightly bigger pieces of the same glass of which tesserae

were made were among the finds. Therefore you find many broken pieces

of tesserae between the smaller shards of glass as they were being

prepared for the melting process.

The production waste consists of molten drops of glass encrusted with

sand as they fell onto the sandy floor of the workshop still soft and

thus sticky. Among those drops of molten glass some have been found of

clear glass with remains of gold hinting at the fact that also tesserae

with gold foil have been molten and reshaped. Shards of glass for

example a reticella shard are also among those re-molten and re-shaped

drops.

<Image 12>

Fig. 12. Examples of half finished or failed beads a: blue bead with

center hole still filled with clay separator, one end partially molten

b-c: a blue and two red beads with traces of being rolled around a

metal spindle d: green bead made of a wound rod e-f: yellow beads made

from tubular rods; two have molten together when the bead maker

attempted to round the edges. Scale: 3:2. (Sketch: P.-O. Bohlin)

<Image 13>

Fig. 13. Examples of reticella rods and beads. Of the two rods a is

made of blue glass with red and white veins (unfinished) and b is blue

glass with red and yellow veins. The beads color scheme is blue, white

and red. Scale: 3:2. (Sketch: P.-O. Bohlin)

<Image 14>

Fig.14. Examples of waste from production a-c: ends of stringers of

green glass with traces of pliers d: millefiori of blue glass with

parallel of blue glass with parallel white and red veins. e: 2

collections of stringers for the creation of millefiori rods made from

red, yellow and blue glass. Scale: 3:2. (Sketch: P.-O. Bohlin)

Only 169 pieces of glass shards have been found. They are predominantly

wall shards of glass items, 25% are shards from edges and 2% shards

from the bottom of a glass item. In 82% of the shards the glass is

light green, 11% dark green and the remaining shards are distributed

between the colors blue, clear, olive colored, brownish red and purple.

Reticella and funnel glasses are the most dominant types of types of

glass containers which means if is mostly drinking vessels that can be

dated into the same time period. It is possible that there are also

older types existent, however, if so then they only occur in

insignificant numbers.

<Image 15>

Fig. 15. Shallow iron pan with even bottom and short handle that has

been found in one of the furnaces of the bead maker. Scale: 4:5.

(Sketch: Moria Mackenzie).

There are only a few hints that the bead maker used shards to create

beads. The existence of glass shards is best explained as sign of

extensive trade with glass drinking vessels that occasionally broke

into pieces during their transport. Similar finds in Helgö and

Birka have been interpreted in the same way.

We are not going to elaborate on the technique of bead production other

than some discoveries made in regards to the tools of the bead maker.

In the workshop layer we found a fist sized stone with a depression in

the center which could have been a mortar. A shallow metal pan with an

almost completely even bottom and a short handle has also been found in

the hearth. It was possibly used to melt glass frit. A bone spatula was

discovered in the workshop layer. An iron stick with conical tip and

wooden handle is considered a scatter find; however, it might be

possible that this is indeed a mandrel or other kind of tool from the

bead maker's workshop. The traces of pliers on monochrome as well as

reticella and millefiori rods have to be mentioned in regards to

discussing tools.

<Image 16>

Fig. 16. Iron rod with conical tip and remains of a wooden handle.

Length 29.5 cm. Was not found in context with function but is likely a

tool of the bead maker. (Photo ASR).

To sum up, the following can be said about the glass trade:

It is the fact that in relation to the number of beads and shards of

other glass items a much larger number of tesserae have been found that

is characteristic for Ribe, in comparison with other places that show

signs of bead production. The following shows what importance the proof

of workshops have on the classification of a finds: The excavation was

executed in two phases which each led to the discovery of about 50% of

the total of found glass material. However, the last phase in which

also the workshops have been discovered provided us with 76% of the

glass rods. This find enables us to more clearly define and classify

the find in its entirety.

The workshops were obviously of a very simple nature. Nothing indicates

a solid construction with walls and roof. The floor was covered with a

layer of sand and measured 4.4m. Unfortunately this is the only

measurement available. The small furnaces of fired clay are on the

ground. The bead maker possibly worked using a low table where he kept

tools and raw materials. Remains of such a table have not been found.

Using crucibles he melted the glass in open furnaces. In order to do so

a temperature of only 1000°C is necessary this can be achieved

by means of bellows. A helper to work the bellows was necessary to

produce a constantly hot fire. This helper might have been helpful

during other steps of the work process as well; however, the main body

of the work was done by the bead maker alone even though two craftsmen

per furnace might have been the ideal cast. With the furnace

immediately on the ground the bead maker must have worked crouched low

and squatting.

Here follows an attempt at explaining the existence of several activity

horizons on top of each other and separated by layers of clean sand. It

is difficult to determine whether the individual layers should be

considered as individual horizons for seasonal reoccurring workshops or

as regularly happening floor reconstructions of a workshop with

continued production. Since there are no signs of a house, the

production possibly took place during the warmer season of the year,

probably during the time when traveling merchants temporarily settled

at a market place. However, there are also arguments against this

theory since the excavated area might have hosted the work shop during

the summer and that the actual workshop of the bead maker has yet to be

found.

The large number of finds scattered all over the area of the

excavations indicate that the two areas classified as bead maker work

shops might not have been the only ones. The beads that can't be dated

due to their type need to be examined as chronologically congruent with

the other finds.

With the provision that this is only a preliminary report it appears

that there has been ample production of glass beads in Ribe before and

after 800 and that there was at least one workshop was active.

Up until today the production of millefiori and reticella beads has not

been thought possible under as simple conditions as in Ribe. The

discoveries of Ribe thus ends a traditional theory that for the

complicated trade of glass bead making you had to look elsewhere like

Italy or even Egypt and Syria. This also meant that this trade had been

preserved in good sized workshops with a long tradition. The glass

finds of Ribe however show that even more complicated and complex

techniques are possible under the fairly primitive and simple

conditions of a market place of pre-urban character.

With the aforementioned caveat in mind one can also assume that the

bead maker was a traveling craftsman, possibly from Western Europe, who

set up shop in Ribe during the trade season. This stay appears to have

been of extended nature and created also a decent production based on

the complicated techniques used in bead production.

It is unthinkable that the bead production was only for the local

market of Ribe; however, it is near impossible to judge the number of

possible customers from the back lands due to the lack of finds of

Danish burial and settlement sites. Thorough studies on the prevalence

of the various types of beads in regards to time and place are still

necessary. As long as it is not possible to study other work shops the

results of excavations will be very vague. In the list of craftsmen of

this study in the northern world the bead maker from Ribe holds a very

high rank.

Amber

A large amount [about 2.2kg] of untreated amber has been found. Among

the amber finds were also 3 pieces that showed preparatory work to

dome-shaped gaming pieces as well as several half finished beads and

pieces with drilling holes. Amber was found scattered through the

layers of phase 2 and phase 3. In connection to an activity horizon in

phase 3 a sand island mixed with chips of amber was discovered. It

cannot be determined accurately whether this was a workplace for a

craftsman working with Amber who would have considered those chips as

usable raw material instead of waste.

Wood

Only half finished items and very few finished objects made from wood

have been found in Ribe and thus there is not much further reason for

continued study from a craft perspective. Remains of wooden

constructions and raw wood only show traces of fairly primitive

processing with a hatchet. The bottom of a wooden well construction is

put together by means of mortise joints. The mortises have been shaped

with a hatchet and the hole at each end has been drilled with a spoon

drill and shaped with a hatchet. This kind of drill is listed with

items with iron components, but not the hatchets.

Four staves have been discovered in the same well. They were made from

oak wood which despite its slow growth displayed 170-180 annual growth

rings on its fairly small width. There has been an attempt at

determining the age by means of a dendrochronological study, however,

the pattern of annual growth rings could not be matched with that of

the area of Slesvig-Jutland. While therefore the trade of coopers does

not appear to be native to Ribe, that of the ship builder is a very

likely possibility. Only one big iron anchor has been discovered in

recent excavations but the many found tacks show the same kind of

breakage as the finds Paviken on Gotland brought to our attention by

Per Lundström.

23

The antler, bone and horn trade24

The finds consist of about 1100 pieces as well as 5-6 liter of stag

antler waste. It was mainly found in the unrotten dung layers of phase

2 which probably relates to the preservation attributes of this layer.

The main item of the finds is production waste.

Only 35 pieces of actual items have been uncovered as there are 12

fragments of combs, 8 gaming pieces, 2 die, 8 Tibia with a hole drilled

into them, 3 needles as well as 2 ”Schlittschuhe/ice

skates”. Individual pieces can originate from a later period.

The distribution of waste and finished items is characteristic for Ribe

except for the bead production and not very surprising. In the

excavated area items were produced, not used.

Antler

One of the pieces of this category stems from a moose; the remaining

pieces are all from stags. Of the preserved antlers [all stag] about

¼ are still with the base whereas the remaining pieces come

from antlers that had been shed naturally. This distribution resembles

the distribution of finds from Hedeby and indicates there as well as

here that not only antler from slaughtered animals were used but that

they also went actively out to collect the raw material for the

intended production. The characteristics of the antler waste in Ribe

resemble that of similar settlements of the same time in the Baltic

area. This indicates a similar work technique and therefore possibly

similar products.

Dr. Ingrid Ulbricht in Sleswig represents the theory that there wasn't

enough demand to justify a professional production during the Viking

age and regards the production of combs as a secondary trade to a

craftsman with a different main job.

However, the striking similarity of waste from place to place appears

to point into a different direction. In Ribe a high concentration of

waste, especially the shavings caused by working the raw material, was

found in a clearly defined area. Despite the fact that no definitive

work shop area was discovered the amount of waste still indicates a

regular trade.

Apart from indirect evidence for the tools in use [knife, saw,

polishing stone] provided by discovered items, only one single tools

has been excavated that might have been used in regards to working with

bone and antler. It is a square block of antler measuring 4.5cm wide

and 1.5cm tall which provides the base to an iron point with a square

profile inserted into its center. This item might have been used as a

clamp of sorts to hold smaller objects in place while they were being

shaped into dome-shaped gaming pieces for example. In finds from Birka

matching indentures in the bottom of such pieces have been found.

Bone

The aforementioned pierced Tibia, needles and "ice skates" do not

indicate that bone has been used in extensive professional production.

This also applies to half finished pieces for the construction of combs

cut from rib bones. However, there might already have been a trade

based production of bone combs in place.

Horn

Items or waste from horn (Keratin) have not been found, except for pegs

from horn of cow, sheep and goat. Those pegs do not show any marks of

manipulation and thus aren't interesting in regards to this report on

crafts in Ribe of the Viking age.

6 joined horn pegs, 66 single pieces and 12 smaller fragments of horn

pegs from goat have been found. Considering the fact that only 6 bones

of goat have been found one cannot doubt the theory that they have been

collected specifically.

Those horn pegs do show marks of manipulation where they have been

sawed or hacked off. This leads to the assumption that goat horns

(keratin) have been used for the production of so far unknown items.

Those horn pegs have been found in the same area as the antler waste.

Working leather25

Leather has been found exclusively in the layers of unrotten dung of

phase 2 where it has been preserved. A total of 430 pieces of leather

have been excavated. An attempt at determining the kind of leather

based on texture and orientation of the hair follicle has been made.

The majority of finds were cow leather, the remaining pieces from

horse, sheep and goat.

<Image 17>

Fig. 17. 2 types of shoe. On the left "skin" shoe made from one piece

and on the right, vamp for shoe with separate sole. (Photo: Marianne

Carlsson).

Apart from the cut off tip of a knife sheath and a peculiar item

resembling a leather key, the most remarkable leather finds are shoes

of which 2 main types have been discovered:

- "skin" shoe made out of one piece of leather

- sole shoes where top and sole have been sewn together

An entirely preserved skin shoe shows that a 5mm strong leather strap

has been used to sew it together. To either side of the foot opening

there is a row of slanted holes used to pull a leather strap through to

tie the shoe tightly to the foot.

Actual yarn has been used to sew the sole shoes together. Remains of

the thread have been preserved and indicate it's been of botanical

nature. The thread was pulled through holes that had been punched into

the leather first. This kind of seam has a very characteristic

appearance and can even be determined on fragments. Two complete uppers

have been excavated, one the upper to a boot, and fragments with part

of a seam. The uppers are cut from one piece of leather in a v-shape

and sewn together at the heel. The technique is similar to the one in

use during the later Middle Ages; however, without using the variety of

sewing techniques with regards to the task at hand as it was the case

in the later Middle Ages. All uppers show traces of the same

decoration: a sewn welt from instep down to the toes. The shape of one

sole indicates a pointed heel whereas two others have a rounded heel.

This is also the case with the preserved boot and it is possible that

shoes had soles that were shaped with a pointed heel.

The technique of cutting the pattern pieces is also different from the

methods used during the later middle ages. While in the later middle

ages the uppers were oftentimes pieced together, a method which

guarantees the best use of the leather, both types of shoes found in

Ribe were cut in a way that would create a rather great amount of

waste.

The remaining leather finds are pieces of various sizes with marks of

manipulation that indicate that they've been cut off along the edges.

This marks them as production waste which in turn indicates that the

leather work shops must have been nearby whereas the other items appear

to be actual waste of the settlement. The waste allows no theory in

what else was produced. A few triangular pieces of leather are probably

related to the v-shaped uppers of shoes.

The sole shoes have been made mostly from goat and sheep leather

whereas the skin shoe was cut from cow leather. The same kinds of

leather dominate the waste. Especially the sole shoes appear to have

been made by a professional shoemaker who managed to achieve a

professional uniformity in his products. The waste indicates that there

was leather trade in Ribe. It is therefore also believable that the

excavated shoes were made in Ribe.

Textiles26

In regards to woven textiles a piece of roughly woven piece of wool and

a finely woven piece of a vegetable fiber, possibly flax, have been

found. Aside from this 100 loom weights and many fragments of fired

clay have been unearthed. Furthermore weights of unfired clay were

discovered but only a few exceptions of those were in a state that

allowed complete excavation. 30 spindles of fired clay and one wooden

spindle were found as well. These finds are distributed over the layers

of phase 2 and 3. There is one area with a certain concentration of

loom weights which were found scattered and not in one row. All other

finds must be regarded as scatter finds.

The question whether there was a weaving trade in Ribe or simply

production for their own use cannot be answered at this point.

One of the major points of discussion is about “how

many” spindles and weights you need to find before you can

consider them “many”. Considering the fact that for

a loom you need at least 15-20 weights a total of 100 found weights is

a rather unimpressive number. On top of that there are also the

fragments and of course that fact that these finds are classified as

scatter finds.

It is near impossible to compare this find to that of other

settlements. Size of the settlement and the style of archaeological

approach as well as time period of the settlements play an important

role. However, while there's hardly any material for comparison there

is the general impression that the concentration of this particular

kind of find in Ribe is unusually numerous.

The zoological side of the studies if this excavation offers

information that might be of interest in this regard. In comparison to

other studies the bone material of Ribe has a greater concentration of

bones from old sheep.

27

This could indicate a greater interest in

the production of wool than keeping sheep for meat. Since there appears

to be evidence for sheep farming aiming for production of wool and

therefore catering to spinning and weaving it raises the question

whether the lengthy production process of making cloth was feasible for

settlements of a temporary/seasonal nature, no matter whether the

production aimed at covering the needs on site or as a trade.

A formula based on the number of found spindles and loom weights that

would allow us to determine the kind of production level of a

settlement would be very helpful to answer this question.

Summary

To sum it up, it can be said that the craft-related finds of the

excavations clearly indicate that in the oldest part of Ribe almost all

crafts known from the Viking age were active. Under this aspect Ribe

can be classified as a fully developed settlement. The discoveries of

the work shops for bronze casting and bead making allow significant and

new contributions to the understanding of the development, the methods

of production and the standing in society of those two trades.

Notable in regards to the bronze casting workshop is the fact that so

much material only provided information on so few different types. This

concentration of one particular kind of brooch in one work shop appears

to indicate a specialization; a thought that'd open up a whole new

horizon of theories. However, we cannot tell for certain whether the

same craftsman tried for diversity in the production of other object

categories or if he managed to hold on don to his specialization for

his whole life. Comparing the limitations of the material of Ribe's

bronze work shop with the great variety of shapes and types of bronze

items of the Viking age it is surprising that not much more waste of

bronze work shops has been discovered.

<Image 18>

Fig. 18. The weights for the loom are mostly plain. Extant ornaments

are circled crosses and indented marks of keys of that type. Scale 2:3.

(Drawing:.Hette Madsen)

While the glass finds haven't been studied under this aspect, the

excavated material suggested a certain level of specialization. An

example is the reticella rods and beads made form these as they are

limited to this one work shop.

The special attributes of the layers of unrotten dung of phase 2

contributed greatly to excavating unusual organic material. Important

are for example the evidence that horn matter [keratin] from goats had

been used for the production of objects. The leather finds contribute

to a better understanding of the craft during this time period since it

is very likely that the shoes were crafted in a highly professionalized

and specialized manufacturing process. It is astounding to find the

primitive skin shoe in the same area as the fully developed shoe with

separate sole and leather upper. This type hasn't been able to date as

early as it has been the case here.

The conserved shoes undoubtedly were considered trash since they are

completely worn out. It is typical for Ribe that excavation produce

mainly waste but no finished items. An exception is the beads that once

lost were hard to recover by the bead maker.

A major part of the production for example bronze items and beads are

luxury items. It is therefore most likely that the finished items were

buried with their owners. This means it is very unlikely to find them

inside the settlement. The odd ratio of waste to finished items is very

apparent in regards to the material found with the comb maker workshop.

Combs are very common objects of every day use, although the

“status” of the comb during that time period is

being discussed, and one would have expected a higher number of used

finished items during the excavation.

In general, the finds of the excavations indicate that the production

of items of society of Ribe was not aimed at satisfying the local

demand only. This discovery leads to the question about the overall

character of the settlement. This problematic has been touched briefly

in earlier chapters without trying to present evidence in a way that

would not lead to the forming of a certain opinion on this matter too

early.

The most striking attribute is the lack of evidence of house

constructions and aside from the remains of the two sheds the overall

lack of marks of settlement. This lack contradicts the richness and

variety of excavated material of this area. Is this evidence enough to

consider a periodical settlement with market character or was there a

constant settlement after all?

Basically it is misleading to present this problem as an either-or

question. The represented crafts cannot be considered indisputable

evidence. They rather tend towards indicating a temporary settlement.

It is also possible that this kind of market place came into existence

following a constant settlement. The question is thus best phrased like

this: Does this find that does not show marks of settlement provide any

evidence for a constant settlement ? With reservation the ploughing

marks of phase 1 can be considered evidence for this idea. The

aforementioned wells and the waste of the smithy do not appear in

direct stratigraphical relation with the ploughing layer. While it is

likely it is not certain that the ploughed fields and the settlement

have been in immediate vicinity of each other. The recovered dung of

domestic animals of phase 2 is another sign, even better than the ones

mentioned so far. However, aside from the fact that the amount of dung

can only originate from domestic animals in barns this is also not an

indisputable evidence to support the theory of a permanent settlement.

One craft, namely the production of cloth, appears to offer the

evidence with the greatest importance. It is the most popular craft in

settlements with agriculture and self-sufficiency and thus provides a

good clue for the existence of a permanent settlement.

As mentioned before there is no probability calculus to determine the

necessary amount of preserved tools before they are considered the

remains of a true craft production with intended sales. In this regard

the finds of Ribe share a striking characteristic that sets it apart

from other prehistoric finds. The bone material shows an excess of

older sheep, ie sheep were kept for wool and less for meat. This also

means that the whole process from sheep to shawl is present. This

process is lengthy and time-consuming and requires a certain

settledness which contradicts the theory of a periodical market place.

In other words, it appears that the production of textiles though

difficult to define as a professional trade offers the best evidence

for a permanent settlement at the northern shore of the Ribe Au in 800

and before that.

----

(1)

Vita S. Anscharii. Script. Rer. Dan. I, 482. 1772. (

back)

(2)

Dipl. Dan.1, I, 319. 1975. RICHERUS:

Historiarum libri IIII. Recogn. Georgius Waitz, 73-74. 1877.

Monumenta Germaniae historica, Scriptorum, III, 395-96. ADAM VON BREMEN:

Hamburgische Kirchengeschichte (ed.B.Schmeidler), 64-65. 1917. (

back)

(3) ADAM VON BREMEN: Op.Cit., 230-31. ANDREAS NISSEN:

Danske Bisperækker, 56-57. 1935. (

back)

(4) ADAM VON BREMEN: Op. Cit., 228-29. (

back)

(5) ELISE THORVILDSEN:

Dankirke und KIRSTEN BENDIXEN:

Menterne fra Dankirke, Nationalmuseets Arbejdsmark, 47 f. 1972. (

back)

(6) OLAF OLSEN:

Nogle tanker i anledning af Ribes uventede høje alder, Fra Ribe Amt XIX, 240. 1975. (

back)

(7) KRISTINA DANIELSSON:

Bearbetat ben och benhorn, Birka, 40 f. 1973. (

back)

(8) Die Münzen werden von

Museumsinspektør Kirsten Bcndixen, Den kgl. Mønt- og

Medaillesamling, Nationalmuseet, bearbeitet. (

back)

(9) MOGENS BENCARD:

Ribes ældste udvikling, Mark og Montre. 1974. MOGENS BENCARD und STINE WIELL:

Et trefliget spænde fra Ribe, Mark og Montre, 1975. (

back)

(10) Die metalltechnischen Untersuchungen werden

von Konservator Helge Brinch Madsen, Konscrvatorskolen,

København, durchgeführt. (

back)

(11) ROBERT THOMSEN u.a.:

Untersuchungen tiur Technologie des Eisens. Ausgrabungen in Haithabu, Bericht 5. 1971. (

back)

(12) P. V. GLOB:

Avlssten, KUML. 1959. (

back)

(13) ELSE ROESDAHL: Fyrkat II, 45. 1977.

Essesteine aus Ton kommen auch in Fyrkat vor, a.a.O.61. Ein schwedisches Beispiel gibt INGA SERNING:

Förhislorisk järnhantering i Dalarna. Järnkontorets Forskning. Serie H, Nr. 9. 1973, 113 f. (

back)

(14) Wie Anm. 10. (

back)

(15) HELGE BRINCH MADSEN:

Specialist i Spænder, SKALK, Nr. 4. 1976. (

back)

(16) Typ 4 ist identisch mit den von Fyrkat erwähnten »heating trays«, siehe RoESDAHI.: Fyrkal II,

S. 51. (back)

(17) Das \laterial wird von al. kand. Ulf

Näsman, Viborg, bearbeitet. Dcm Kunsthandwerker Finn Lynggaard

ist air Ratsrhlüge über herstellungstechnische Fragen zu

danken. (back)

(18) BIRGITTE: \\'ISTOE`r: I'iklaria fra Ribe. Alark og Alonlre, 1978. (back)

(19) JOHAN CALLMER: Trade beads and head trade in Scandinavia ca. 800-1000 A.D. Lund 1977. (back)

(20) Vergleiche AGNETA LUNDSTRÖM: Bead making in Scandinavia in the Early Middle Ages, Antikvarisk Arkit 61. 1976. (back)

(21) DAN CARLSSON: Ett vendel - vikingatida verkstadshus på Gotland. Fornvãnnen. 1976/3-4. 86 f. (back)

(22) AGNETA LUNDSTROM.a.a.O. (back)

(23) PER LUNDSTRÖM: Kinknaglarnas vittnesbörd, Sjöhistorisk årsbok. 1971-72. (back)

(24) Das Material wird von fib kand. Kristina Ambrosiani, Stockholm, bearbeitet. (back)

(25) Das Material wird von cand. mag. Ingrid Nielsen, Sydjysk Universitetscenter, bearbeitet. (back)

(26) Das Material wird von mag. art. Lise Bender Jorgensen, Langelands Museum, bearbeitet. (back)

(27) Das Knochenmaterial wird von Museumsinspektor Tove Flatting, Zoologisk Museum, bearbeitet. (back)

Dark Ages Re-Creation Company

Dark Ages Re-Creation Company